DESCRIPTION

Part1. Machine description:

1. Main part: The frame of the whole machine adopts national standard 10# channel steel to ensure the stable performance of high-speed operation.

2. Feeding part: the lifting method of the air expansion shaft driven by the cylinder and pneumatic double arms, equipped with a 76mm expansion air expansion shaft.

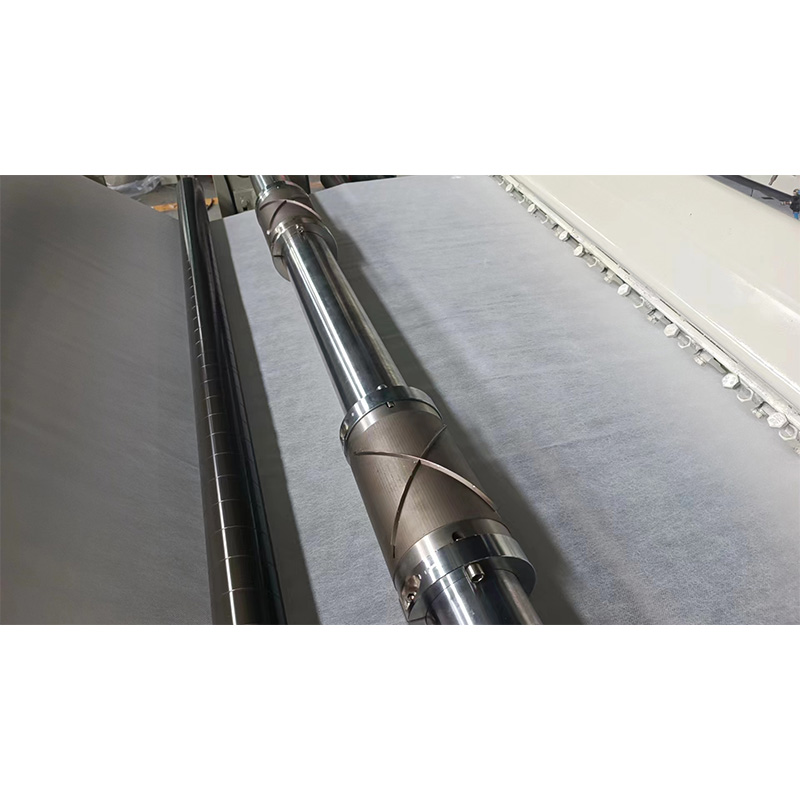

3. Feeding part: steel and rubber rollers are conveyed simultaneously.

4. Conduit part: all use high-precision hard anodized aluminum alloy wrinkle-removing roller guide cloth, and all achieve dynamic balance.

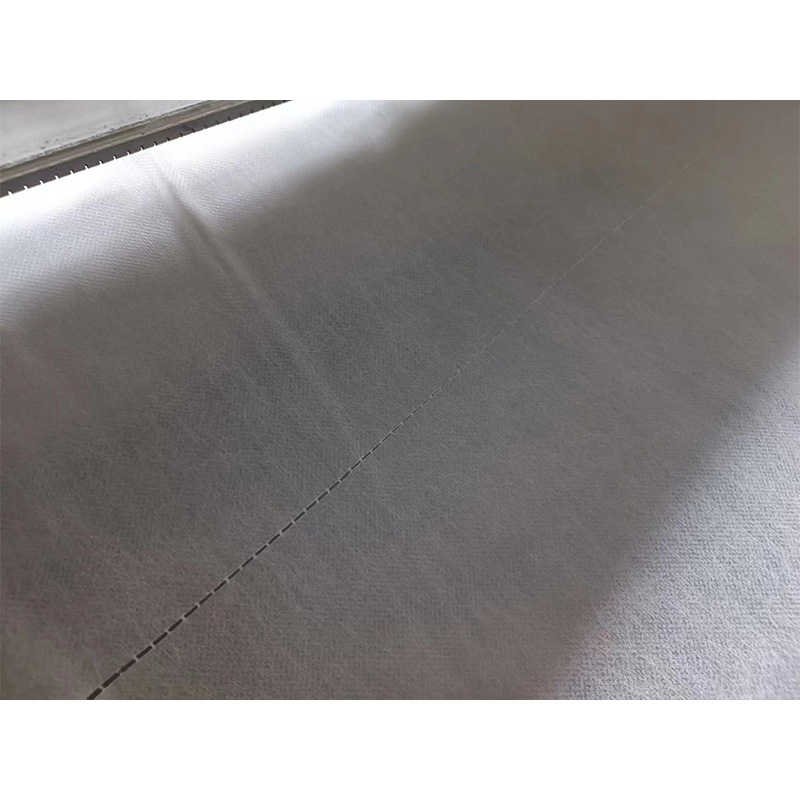

5. Break point part: Servo motor with spiral bonding method, light and low noise. (Line spacing ≥10cm adjustable)

6. Slitting part: Use 10 sets of upper and lower air knives for slitting.

7. Winding part: double-roller surface winding, and is equipped with aprecision proportional valve to control the entire exhaust pressure and compression adjustment And with a winding 76mm air shaft.

8. Counting part: photoelectric induction (encoder counting function) is adopted.

Part 2. Main technical parameters:

1. Rewinding diameter: ≤350mm

2. Unwinding diameter: ≤1000mm

3. Inner diameter of paper tube: 76mm

4. Effective width: 1800mm

5. Roller surface width: 1850mm

6. Mechanical speed: 50-80M/min, the operating speed can be limited according to the requirements of the other party;

7. Counting accuracy:±0.5%

8. Winding neatness:±2.0mm;

9. Maximum loading and unloading weight 300KG;

10. The weight of the whole machine is about 2200KG;

11. Compressed air pressure requirement: about 6KG.

Hot selling countries: Non Woven Spa Bed Sheets Rewinding Machine is well sold in Austria, Singapore,Malaysia,Indonesia, India, Russia, Japan,Thailand etc.