Futuristic Fabric Handling: The Large Non-Woven Rewinding Machine Advantage

In the intricate landscape of non-woven materials processing, the Large Non-Woven Rewinding Machine emerges as a groundbreaking leap forward, eclipsing conventional counterparts like the Non-Woven Rewinding Machine, Automatic Non-Woven Rewinding Machine, and other fabric rewinding equipment. This cutting-edge piece of machinery introduces a myriad of unparalleled features, reshaping the benchmarks for efficiency and customization within the industry.

- Enhanced Embossing and Roll Design: Elevating Versatility At the core of the Large Non-Woven Rewinding Machine lies a rewinding roll on the slitter rewinder, meticulously crafted with pneumatic knives, knurls, and electroplating for exceptional longevity. The machine’s versatility extends further with large-scale embossing units, showcasing an electroplated roll and a wool-covered roll. The ability to customize embossing patterns caters precisely to the diverse requirements of customers, setting it apart as an innovative choice in the realm of Non-Woven Rewinding Machines.

- Precision in Web Feeding and Conveyance: Setting New Standards The Large Non-Woven Rewinding Machine integrates a pneumatic automatic web feeding device, coupled with an air-operated wide belt conveyance system. This dynamic system not only ensures precision in material handling but also incorporates automatic counting and stop functions through infrared ray technology. This marks a paradigm shift in Automatic Non-Woven Fabrics Rewinding Machines, establishing a new standard for precision and automation.

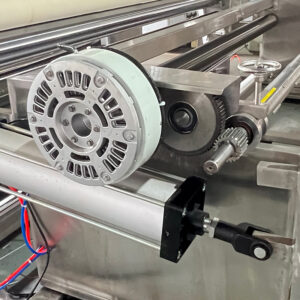

- Extended Service Life and Variable Speed Control: Maximizing Efficiency Leveraging an air-operated lifting device for slitting knives, the Large Non-Woven Rewinding Machine significantly enhances the service life of these crucial components. Moreover, the rewinding roll boasts a variable speed control unit, allowing automatic adjustments in rewinding speed—a feature conspicuously absent in traditional Non-Woven Material Rewinders. This combination of durability and efficiency sets a new benchmark in the industry.

- Integrated Control for Adjustable Perforating Pitch: Precision Redefined The harmonious integration of the Programmable Logic Controller (PLC) and servo motor in the Large Non-Woven Rewinding Machine enables seamless adjustments in perforating pitch—an advanced capability absent in basic Non-Woven Material Rewinder Machines. This precision control mechanism enhances the machine’s adaptability to various production requirements, ensuring unparalleled customization.

- Versatility in Speed and Size Adjustability: Adapting to Dynamic Needs Setting itself apart from conventional Non-Woven Fabrics Rewinding Equipment, the Large Non-Woven Rewinding Machine offers adjustable speeds for embossing, scoring, slitting, and rewinding. Additionally, it provides the flexibility to adjust slitting sizes at will, meeting the dynamic needs of diverse production scenarios. This adaptability makes it a cornerstone for efficiency in the non-woven materials processing landscape.

- Durable Construction for Prolonged Performance: Crafted for Excellence Critical components impacting production quality in the Large Non-Woven Rewinding Machine are exclusively crafted from stainless steel, ensuring unparalleled durability. Electroplating adds an extra layer of assurance, guaranteeing rust and delamination resistance for up to 2 years—a commitment that distinguishes it from typical Non-Woven Fabrics Roll Goods Processing Equipment.

In conclusion, this innovative machinery not only addresses the evolving needs of the industry but also sets formidable benchmarks for efficiency, adaptability, and durability in non-woven materials processing. The Large Non-Woven Rewinding Machine is more than a piece of equipment; it is a transformative force, reshaping the landscape of non-woven materials processing with its advanced features and groundbreaking capabilities.