Streamlined Efficiency: Innovating Non-Woven Printing and Folding Machinery for Enhanced Manufacturing

Table of Contents:

I. Introduction of non woven printing and folding machine

Ii. Product details of non woven printing and folding machine

Iii. Specifications of non woven printing and folding machine

ⅳ. Key features of non woven printing and folding machine

ⅴ. Conclusion

I. Introduction of non woven printing and folding machine

The AQ-F (300-600) machine has been praised for its versatility in being capable of implementing fully automatic processes to non-woven and air-laid paper from web feeding to conveying, printing, drying, folding, cutting, and counting all the way to the finished product. This non-woven printer folder uses an anilox roller and rubber roller to print, which ensures the printing accuracy, low cost, clear printing, fast drying time, and folding convenience.

The folding machine has a multifunction shape folding device, which allows for various folding patterns, such as the N shape, W shape and special shape foldings, as well as folding in half. The size of the finished product that has been folded by this non-woven folding machinery ranges from 300-600mm.

II. Product Details of Non Woven Printing And Folding Machine

1. Dimensions of 280mm folding machine: approximately 3.851.051.75m (LWH).

2. Each M-F machine is designated according to its product’s fixed length, offering versatility in sizes ranging from 280230mm to 280330mm.

3. Compatible with spunlace nonwoven, airlaid paper, wood pulp material, composite nonwoven materials, etc.

4. Performance includes folding, printing, cutting (utilizing band-saw for neat edges), pneumatic counting, and adjustable speed.

5. Sturdy construction with thicker iron board for the working table and technical enhancements for noise reduction.

6. Equipped with a broad-strap synchronous transferring device for tension control and adjustable speed for different fabric types.

7. Utilizes high-quality materials such as Chinese 45# steel for axletrees and stainless steel for plywood.

8. Features automatic shaping knife, automatic counting, and stability-enhancing design elements.

9. Axletrees are made of Chinese 45# steel, with noise reduction measures and stainless steel control board.

10. Optional features include imported cutting tools, automatic cutter sharpening unit, web guiding system, static removal device, and embossing unit.

III.Specifications of Non Woven Printing And Folding Machine

Model: AQ-F (300-600)

Folding size: 300-600mm (It can be customized)

Folding device: High precision linear cutting technology

Folding patterns: N shape, W shape, folding in half and special shapes

Control system: Frequency control

Power: Motor

Speed: 200-500 sheet/min

Compressed air: Customers prepare for themselves

Power supply: 220V, 50Hz, 3.5-6.5Kw

Weight: about 2500kg (Specific weight depends on machine configurations)

Ⅳ. Key Features of Non Woven Printing And Folding Machine

1. This type of non-woven folding machine uses imported cutting tools that are durable, and have a great heat resistance. In addition, it comes with an automatic cutter sharpening unit.

2. It is equipped with an automatic counting device and a web guiding system.

3. The air-laid paper folder uses a special gar transmission to eliminate the gear clearance. It can also be equipped with a static removal device and an embossing unit if required.

4. The wide belt conveying device and tension control devices are equipped in order to ensure the size accuracy of the folded products.

5. The machine table and parts that touch the product are all constructed using stainless steel, which ensures the safety and hygiene of the products and machine.

6. Our color printing folding machine features a variable frequency speed control. The wiring on the frequency converter is stabilized and safe.

7. This folding machine can also be equipped with a special shape folding unit, which allows for more shapes and folding methods.

Ⅴ. Conclusion

In conclusion, the AQ-F (300-600) cleaning rag production line presents a comprehensive solution for streamlined manufacturing of non-woven cleaning rags. With its versatility, precision, and array of features including automatic processes, durable construction, and optional enhancements, this production line stands as a reliable choice for meeting the demands of modern manufacturing processes.

Video:

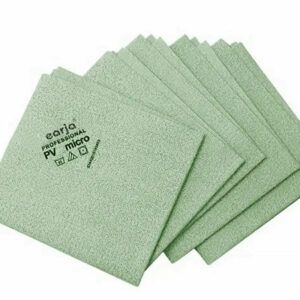

Final Product: