Transformative Technology: Non Woven Folding Machines Revolutionize Production

Non woven folding machines have emerged as a crucial component in the world of manufacturing, offering innovative solutions to streamline production processes. These non woven folding machines play a pivotal role in various industries, from textiles to medical, and their versatility is matched by their efficiency. In this article, we’ll delve into what non woven folding machines are, how they are classified, and their diverse range of applications.

1. What Are Non woven Folding Machines?

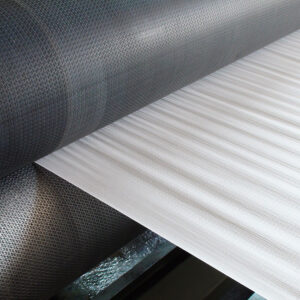

Non-woven folding machines stand as sophisticated machinery engineered to swiftly and precisely fold non-woven fabrics. Typically composed of synthetic fibers, these fabrics boast qualities such as strength, breathability, and cost-effectiveness, making them pivotal across diverse industries. To efficiently process these materials, specialized equipment like non-woven folding machines becomes crucial.

Operating with intricate mechanisms, these machines excel in folding non-woven fabric with unparalleled precision and consistency. Their versatility is showcased in their ability to accommodate various fabric types and sizes, establishing them as indispensable tools for manufacturers working with non-woven materials. As these advanced machines continue to redefine efficiency in fabric processing, they play a vital role in meeting the evolving demands of modern manufacturing.

2. Classification of Non woven Folding Machines

Non-woven folding machines exhibit a diverse range of classifications, each catering to specific needs within the industry, showcasing their adaptability and versatility:

a. Non-woven Folding and Cutting Machine: At the core of the non-woven fabric industry, this machine stands as a versatile workhorse. Its multifunctionality allows for precise folding and cutting, streamlining the production process and enhancing overall efficiency.

b. Non-woven Folding and Printing Machine: This specialized equipment goes beyond mere folding by incorporating printing or branding capabilities into the process. Beyond functionality, it adds a layer of customization, making it a valuable asset for industries where branding is crucial.

c. Non-woven Embossing and Folding Machine: Elevating the aesthetic appeal and functionality of non-woven fabrics, this machine not only folds but also imparts textured patterns or embossing to the material. The result is a three-dimensional design that enhances the visual and tactile qualities of the fabric, opening up new possibilities for creative applications.

d. Customized Folding Machines: Acknowledging the diverse needs of manufacturers, some providers offer tailored solutions with customized non-woven folding machines. These machines are adaptable and can be fine-tuned to meet specific production requirements, providing a bespoke approach to fabric processing.

These various classifications underscore the flexibility and innovation embedded in non-woven folding machines, showcasing their ability to address a spectrum of production demands while introducing unique features that contribute to the advancement of the non-woven fabric industry. As technology continues to evolve, these machines play a pivotal role in shaping the future of fabric processing, offering tailored solutions for diverse applications.

3. Applications of Non woven Folding Machines.

Non-woven folding machines play a pivotal role in diverse industries, showcasing their versatility and applicability:

a. Medical and Hygiene Products: In the realm of medical and hygiene product manufacturing, non-woven folding machines are indispensable. They contribute to the production of medical gowns, face masks, and disposable hygiene products, ensuring precise folding that adheres to stringent quality and safety standards.

b. Textiles: The textile industry benefits significantly from non-woven folding machines, utilizing them to create neatly folded fabrics for an array of products such as clothing, bedding, and home furnishings. The machines enhance efficiency and precision in textile processing.

c. Agriculture: Within agriculture, non-woven materials are extensively used for crop protection and ground cover. Non-woven folding machines aid farmers in efficiently preparing and installing these materials, streamlining agricultural processes and enhancing overall productivity.

d. Packaging: Non-woven fabrics find applications in the packaging industry, and non-woven folding machines play a crucial role in ensuring these materials are neatly folded for packaging purposes. This not only enhances the presentation of the packaged goods but also contributes to efficient packaging processes.

As these machines continue to evolve, their widespread use across various industries underscores their importance in enhancing manufacturing efficiency, meeting specific industry requirements, and contributing to the development of innovative products. The adaptability of non-woven folding machines positions them as integral tools in the contemporary landscape of diverse manufacturing sectors.

In conclusion, non woven fabric folding machines are instrumental in optimizing production efficiency across a multitude of industries. Their ability to fold fabric makes them an invaluable asset in modern manufacturing. As industries continue to innovate, nonwoven fabric folding machines will remain at the forefront of this evolution, contributing to increased efficiency and quality in production processes.

-300x300.jpg)