Exploring Precision in Labeling: The Round Bottle Labeling Machine

Technical parameters of round bottle labeling machine:

The Round Bottle Labeling Machine, often referred to as a bottle labeler, is an advanced piece of equipment designed to provide versatile labeling solutions. To ensure optimal performance, the machine boasts the following technical specifications:

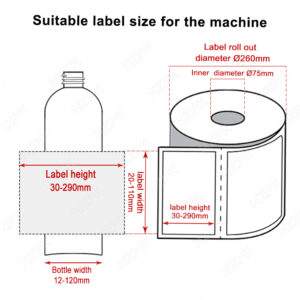

1. Label Size: Bottom line width 10-120mm (infinite length)

2. Labeling Speed: 0-25m/minute (Freely adjustable)

3. Labeling Accuracy: 1mm

4. Applicable Power Source: 110V/220V, 50/60Hz, 400W

5. Canister Diameter: 100mm (Customizable)

6. Dimensions: 2050mm×900mm×1320mm

7. Weight: 75kg

8. Carton Size: 2300mm×1150mm×1600mm

9. Packing Weight: 272kg

These technical parameters showcase the machine’s capacity to handle various label sizes and its adaptability to different production environments. With precise labeling accuracy and adjustable features, it stands as a reliable solution for diverse industries.

Features of round bottle labeling machine:

The Round Bottle Labeling Machine incorporates cutting-edge features that contribute to its efficiency, ease of operation, and adaptability. Key features include:

1. Sturdy Construction: The labeling equipment is constructed using S304 stainless steel and anodizing high-grade aluminum alloy, ensuring durability and resistance to corrosion.

2. Precision Labeling: Driven by a Japanese brand stepping motor, the label applicator ensures high labeling accuracy, allowing for consistent and reliable performance.

3. Advanced Electronics: All electric eyes integrated into the machine are sourced from reputable Japanese or German brands, ensuring quality and reliability.

4. User-Friendly Interface: The machine applies PLC technology with a large human-computer interface, making it easy to operate and providing flexibility for adjustments.

5. Adjustability: The labeling position, height, and angle are fully adjustable, offering versatility to accommodate various bottle shapes and sizes.

6. Single or Combined Operation: Suitable for single-person operation, the machine can also be seamlessly integrated into a wet wipe production line, showcasing its adaptability to different production setups.

These features collectively position the Round Bottle Labeling Machine as a sophisticated and user-friendly solution for businesses seeking efficient and precise labeling processes.

Applications of Round Bottle Labeling Machine:

The Round Bottle Labeling Machine proves its versatility by effortlessly applying labels to cylindrical products. From pharmaceuticals to food and beverage packaging, its adaptability shines through. Its efficiency in maintaining high labeling accuracy makes it an indispensable asset across various industries.

Additional Features and Customization:

Our Round Bottle Labeling Machine goes beyond conventional labeling, emphasizing its exceptional customizability. Tailoring to diverse needs, we offer a spectrum of options, from size customization to adjusting input material width and production speed. This flexibility positions our machine as a frontrunner in the labeling machinery landscape.

Beyond its fundamental specifications, the Round Bottle Labeling Machine boasts an array of advanced features, emphasizing its position as a cutting-edge solution for diverse labeling needs.

1. Material Quality Assurance: Crafted with meticulous attention to detail, the machine features construction using S304 stainless steel and anodized high-grade aluminum alloy. This not only ensures longevity but also safeguards against corrosion, meeting the highest standards of material quality.

2. Precision-Driven Labeling: The heart of the machine lies in its label applicator, powered by a Japanese brand stepping motor. This precision-driven mechanism guarantees high labeling accuracy, a critical factor in industries where consistency is paramount.

3. Global Electronic Components: The reliance on electric eyes from reputable Japanese or German brands underscores the commitment to global standards. These components contribute to the machine’s reliability, durability, and consistent performance over time.

4. Intuitive Human-Computer Interface: Equipped with a PLC system and a large human-computer interface, the machine ensures a user-friendly experience. Operators can easily navigate through settings, making adjustments with simplicity and efficiency.

5. Versatile Adjustability: The labeling machine offers extensive adjustability options, allowing users to modify labeling positions, heights, and angles. This adaptability ensures compatibility with a wide range of bottle shapes and sizes, providing a flexible solution for varied product lines.

6. Integration Capabilities: Designed for versatility, the machine is not limited to standalone operation. It seamlessly integrates into production lines, particularly in industries like wet wipe manufacturing. This flexibility speaks to its capacity to complement and enhance diverse manufacturing setups.

Customization for Diverse Needs:

Understanding the unique demands of different industries, our Round Bottle Labeling Machine is not a one-size-fits-all solution. It comes with the added advantage of customization options:

1. Tailored Label Sizes: The machine can be tailored to accommodate specific label sizes, catering to the distinct requirements of various products and industries.

2. Variable Canister Diameters: With the flexibility to customize canister diameters, the machine ensures compatibility with different container sizes, offering a bespoke labeling solution.

3. Adaptable Speed Settings: Recognizing the need for speed in production environments, the machine allows for adjustable labeling speeds. This adaptability ensures efficiency without compromising precision.

4. Size Flexibility: Beyond its standard dimensions, the machine can be tailored to different sizes, providing businesses with the freedom to choose a configuration that aligns with their spatial constraints and production scale.

Meeting High Standards with R&D Expertise:

In conclusion, the Round Bottle Labeling Machine stands as a pinnacle of technological ingenuity, seamlessly blending precision, adaptability, and efficiency. Its diverse applications and customizable features make it a valuable asset across industries, while our dedicated team’s commitment to innovation ensures that we not only meet but exceed the evolving needs of our clients. As we continue to push the boundaries of labeling technology, we invite you to explore the limitless possibilities with our state-of-the-art solutions, providing a seamless and reliable labeling experience for your unique requirements. Your success is our driving force, and we look forward to shaping the future of labeling together.