Revolutionizing Towel Manufacturing with Non Woven Soft Towel Machine

I. Introduction: Unveiling the Next Era: Non Woven Soft Towel Machine The Non Woven Soft Towel Machine marks a significant leap in towel manufacturing technology. Building upon the success of the first generation, this machine is equipped with advanced features designed to produce larger-sized towels efficiently and precisely.

In the next section, we will explore the technological marvels that make this machine stand out, starting with the revolutionary Infrared Dual-Count Technology.

II. Technological Marvels:

A. Infrared Dual-Count Technology: Precision at its Peak The inclusion of Infrared Dual-Count Technology signifies a paradigm shift in precision for towel manufacturing. This advanced feature ensures accurate counting, contributing to the overall quality and consistency of the produced towels.

B. Raw Material Handling Efficiency: Streamlining Production With an effective raw material width of ≤ 350 mm, the machine optimizes raw material handling efficiency. The addition of a robust conveyor belt further streamlines the production process, accommodating various raw materials for diverse production needs.

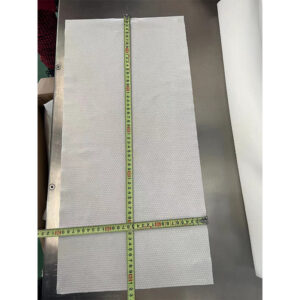

C. Multi-Functional Folding Board: Versatility Unleashed The multi-functional folding board adds a layer of versatility to the machine, enabling the production of larger-sized towels, particularly addressing the demand for 30*60cm towels. Precision in folding is guaranteed, allowing for varied towel sizes.

In the subsequent section, we will explore the dimensions and perforation capabilities of the towels produced by this innovative machine.

III. Towel Dimensions and Perforation:

A. Maximum Diameter and Perforation Distance: Expanding Towel Possibilities The Non Woven Soft Towel Machine boasts a maximum finished product diameter of 300mm, pushing the boundaries of towel dimensions. Additionally, the perforation distance ranges from 10cm to 50cm, offering flexibility in customization and meeting diverse market demands.

B. Real Spiral Perforating Effect: Aesthetic Excellence The real spiral perforating effect adds an aesthetic touch to the towels, creating a light and smooth finish. This unique feature sets a new standard in the industry, providing towels with an elegant appearance.

C. Gear-Type Transmission: Seamless Adjustments for Varied Lengths The machine is equipped with a gear-type continuously variable transmission with perforated pitch set, allowing for seamless adjustments without the need for manual gear changes. This feature ensures efficient and flexible production, adapting to different towel lengths.

Continuing to the next section, we will explore the durability, aesthetics, and user-friendly operation of the Non Woven Soft Towel Machine.

IV. Durability and Aesthetics:

A. Antirust Spray Paint and Stainless Steel Construction: Enduring Quality Crafted with durability in mind, the machine features an antirust spray paint finish and main components made of stainless steel. This design ensures longevity, resilience against rust, and the ability to withstand the rigors of continuous production.

B. Clean Appearance and Smooth Operation: Aesthetic Excellence The Non Woven Soft Towel Machine not only excels in functionality but also in aesthetics. Its clean appearance, coupled with smooth operation, creates an environment of operational excellence. The sleek design adds a touch of sophistication to the manufacturing process.

In the next section, we will delve into the user-friendly operation of the machine, focusing on features like frequency conversion control speed, wiring excellence, and the overall positive user experience.

V. User-Friendly Operation:

A. Frequency Conversion Control Speed: Adapting to Dynamic Production The machine’s frequency conversion control speed allows for dynamic adjustments, catering to various production speeds. This adaptability ensures that the machine can seamlessly integrate into different manufacturing environments, optimizing efficiency.

B. Wiring Excellence: The Beauty of Functionality Electrical parts of the Non Woven Soft Towel Machine adhere to a reasonable standard, ensuring not just functionality but also a visually pleasing wiring layout. This commitment to wiring excellence contributes to the overall ease of operation.

C. Rewinding Speed and Accuracy: Garnering User Praise Users have praised the machine for its clean appearance, smooth operation, and outstanding rewinding speed and accuracy. This positive feedback is a testament to the machine’s performance and its ability to meet user expectations.

Moving forward, we will explore the versatility of the Non Woven Soft Towel Machine in producing perforated and non-perforated towels to meet diverse market demands.

VI. Versatility in Products:

A. Producing Perforated and Non-Perforated Towels: Meeting Varied Demands One of the standout features of the machine is its capability to produce both perforated and non-perforated towels. This versatility ensures that manufacturers can meet the specific demands of different markets and applications.

B. Tailoring Towels for Diverse Applications: A Multifaceted Machine The Non Woven Soft Towel Machine goes beyond the conventional, catering to diverse applications. Whether for medical, hospitality, or industrial use, the machine’s adaptability makes it a multifaceted solution for varying towel needs.

In the next section, we will explore how the Non Woven Soft Towel Machine is positioned in the global landscape, serving international markets and providing customization services.

VII. Operating in the Global Landscape:

A. Serving International Markets: A Trusted Supplier Perspective As a trusted supplier, the Non Woven Soft Towel Machine transcends borders, serving international markets. Its advanced features, coupled with a commitment to quality, position it as a reliable choice for manufacturers worldwide.

B. Customization Services for Global Clients: Bridging Unique Needs Understanding the diverse needs of global clients, the machine offers customization services. This flexibility ensures that manufacturers can tailor their production processes to meet specific regional or industry requirements.

C. Competitive Pricing Strategies: Balancing Quality and Cost To further enhance its appeal in the global market, the Non Woven Soft Towel Machine adopts competitive pricing strategies. Balancing quality and cost, it aims to provide value for manufacturers seeking an efficient and cost-effective solution.

Continuing to the next section, we will gain insights into the towel manufacturing process, exploring different types and applications, as well as addressing common challenges in production.

VIII. Towel Manufacturing Insights:

A. Exploring the Production Process: Craftsmanship in Action Delving into the intricacies of the towel manufacturing process, the Non Woven Soft Towel Machine showcases craftsmanship in action. From raw material handling to the final stages, each step is meticulously executed to ensure consistent quality.

B. Types and Applications of Soft Towels: Adapting to Industry Standards The machine adapts to industry standards by offering a diverse range of soft towels. From healthcare to hospitality, the Non Woven Soft Towel Machine caters to various applications, ensuring that the towels produced meet or exceed industry expectations.

C. Navigating Challenges in Production: Ensuring Consistency While the towel manufacturing process may present challenges, the Non Woven Soft Towel Machine is designed to navigate them seamlessly. Implementing quality control measures, it ensures consistency in production, addressing potential hurdles with efficiency.

In the subsequent section, we will address common questions and concerns that potential buyers may have, providing a comprehensive FAQ Tips module for their reference.

IX. FAQ Tips for Buyers:

A. Ten Essential Questions for Prospective Buyers: A Buyer’s Guide Prospective buyers are encouraged to explore crucial questions before making a purchase. This buyer’s guide covers ten essential questions that delve into the machine’s features, capabilities, and support services.

B. Troubleshooting Guide for Operational Queries: Ensuring Seamless Operations To assist users in maximizing the machine’s potential, a troubleshooting guide is provided. This guide addresses common operational queries, offering practical solutions to ensure seamless and efficient production.

C. Comprehensive User Support and Assistance: Beyond the Purchase The commitment to buyer satisfaction extends beyond the purchase. The Non Woven Soft Towel Machine provides comprehensive user support and assistance, ensuring that users receive ongoing guidance and assistance throughout their machine’s lifecycle.

Concluding our exploration, the final section will emphasize the excellence of the Non Woven Soft Towel Machine, offer a glimpse into future innovations, and encourage potential buyers to connect for their towel manufacturing solutions.

X. Conclusion:

A. Reinforcing Excellence: Non Woven Soft Towel Machine Summarizing the key features and advantages of the Non Woven Soft Towel Machine, this section reinforces its excellence in towel manufacturing. Users are reminded of the machine’s unique capabilities and the value it brings to their production processes.

B. Toward Future Innovations: A Glimpse into Tomorrow The Non Woven Soft Towel Machine stands not only as a pinnacle of current technology but also as a precursor to future innovations. This section provides a glimpse into the evolving landscape of towel manufacturing and the machine’s role in shaping it.

C. Connect with Us: Your Partner in Towel Manufacturing Solutions The article concludes by inviting readers to connect with the creators of the Non Woven Soft Towel Machine. Emphasizing the role of the machine as a partner in towel manufacturing solutions, potential buyers are encouraged to explore the possibilities and enhance their production capabilities.