Cutting-Edge Innovation: Non Woven Folding Machine Redefines Multifunctional Folding

————

————

Part 1. Introducing the Non Woven Folding Machine:

This cutting-edge non-woven machine is engineered to seamlessly handle a myriad of non-woven materials, offering an automatic, all-in-one solution from embossing to folding, counting, and cutting. Notably, the machine features an automatic embossing function, ensuring the creation of intricate and visually appealing patterns without the need for manual folding.

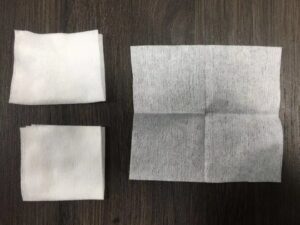

Our non-woven fabric embossing, folding, and cutting machine boasts an impressive speed ranging from 300 to 500 sheets per minute, accommodating folding sizes ranging from 150 to 1000 mm. What sets this machine apart is its capability to fold materials into various shapes, including N, W, and half-folding, as well as other unique configurations.

As a leading non-woven folding machine manufacturer, we take pride in delivering an automatic solution for non-woven fabric folding and cutting. This versatile machine effortlessly completes the entire production process for wet tissue, starting from large Non-Woven Fabric rolls. Its functionalities include cutting, automatic folding, wetting, counting slices, packaging, and automatic product output.

Compatible with a range of materials such as Spunlaced Nonwoven fabric, Hot-dissolved-type nonwoven cloth, Hot Air-through bonded Nonwoven fabric, and Calendar bonded Nonwoven fabric, this machine stands as a pinnacle of efficiency and innovation in fabric processing.

————

Part 2. The Non Woven Folding Machine has been improved and innovated:

Our commitment to technological advancement and innovation shines through in the Non Woven Folding Machine. The key innovation lies in the full adoption of ultrasonic bonding throughout the entire production process, ensuring a superior level of product cohesion. This groundbreaking approach showcases our company’s sensitivity to technological development and unwavering commitment to innovation.

Moreover, the production of this machine incorporates new techniques, materials, and design principles, demonstrating our dedication to pushing the boundaries of traditional fabric processing. The infusion of cutting-edge technology and forward-thinking design philosophy positions our Non Woven Folding Machine as a frontrunner in the industry.Highlighting our pursuit of excellence, we’ve significantly enhanced the machine’s performance. The introduction of new products has led to improved production speeds, resulting in faster and smoother operations.

Notably, our machine allows customizable production speeds, offering higher efficiency, lower energy consumption, and extended lifespan. This emphasis on performance upgrades underscores our continuous efforts to deliver state-of-the-art solutions to our valued customers.Drawing inspiration from the referenced content, our Non Woven Folding Machine is equipped with online cutting features, gas processing feeding equipment, and efficient broad strap transferring. The adoption of PLC computer program control technology, touch screen, transducer, and other cutting-edge components ensures a streamlined and user-friendly operation.The machine’s structure is compact, providing stability and smooth operation even at high speeds. Crafted from stainless steel in compliance with sanitary standards, it adheres to advanced design theories, making it a popular choice domestically and internationally.For continuous fabric processing, the automatic folding of nonwoven drapes involves several seamless operations, including unwinding the nonwoven fabric, lengthwise folding (with two possible types), detachment of the folded length through rotary cutting, folding of the finished drape (with three possible types), and output of the final product onto an out-feed table. This continuous process incorporates automatic control of product parameters, allowing the storage of product recipes for diverse drape formats.In essence, our Non Woven Folding Machine stands as a testament to our unwavering commitment to innovation, technological excellence, and delivering cutting-edge solutions to meet the evolving needs of the fabric processing industry.

Notably, our machine allows customizable production speeds, offering higher efficiency, lower energy consumption, and extended lifespan. This emphasis on performance upgrades underscores our continuous efforts to deliver state-of-the-art solutions to our valued customers.Drawing inspiration from the referenced content, our Non Woven Folding Machine is equipped with online cutting features, gas processing feeding equipment, and efficient broad strap transferring. The adoption of PLC computer program control technology, touch screen, transducer, and other cutting-edge components ensures a streamlined and user-friendly operation.The machine’s structure is compact, providing stability and smooth operation even at high speeds. Crafted from stainless steel in compliance with sanitary standards, it adheres to advanced design theories, making it a popular choice domestically and internationally.For continuous fabric processing, the automatic folding of nonwoven drapes involves several seamless operations, including unwinding the nonwoven fabric, lengthwise folding (with two possible types), detachment of the folded length through rotary cutting, folding of the finished drape (with three possible types), and output of the final product onto an out-feed table. This continuous process incorporates automatic control of product parameters, allowing the storage of product recipes for diverse drape formats.In essence, our Non Woven Folding Machine stands as a testament to our unwavering commitment to innovation, technological excellence, and delivering cutting-edge solutions to meet the evolving needs of the fabric processing industry.

————

Part 3. Features of the Non Woven Folding Machine:

Precise Temperature Control: The folding machine incorporates a constant heating system with temperature control devices and relevant electrical components, allowing for adjustable temperature settings.

Accurate Size Assurance: A synchronous broad belt conveying device and a tension control device work in tandem to ensure the precise size accuracy of the finished product.

Efficient Counting Mechanism: The machine utilizes an air-operated counting device, coupled with both forward and reverse web guiding devices, enhancing the efficiency of the counting process.

Versatile Folding Patterns: A specially designed shape folder accompanies the non-woven fabric folding machine, offering versatility by ensuring a wide variety of folding patterns to meet diverse production needs.

Gear-Driven Precision: The drive part on the textile machine employs gear movements to eliminate gear clearance, and it can be equipped with a static eliminating device for enhanced precision.

User-Friendly Variable Frequency Speed Control: Our folding machine operates seamlessly with variable frequency speed control systems, providing users with easy and customizable operation.

————

Part 4. Advantages of Non Woven Fabric Folding Machines:

Increased Efficiency: Non-woven fabric folding machines are engineered for high precision and efficiency, significantly outperforming manual labor. This efficiency not only reduces production time but also leads to substantial labor cost savings.

Precision and Consistency: Equipped with advanced technology, these machines ensure precise folding and cutting, resulting in uniform product dimensions. This level of consistency is vital, especially in industries where non-woven fabrics are utilized for medical supplies, meeting stringent quality standards.

Waste Reduction: Through optimized cutting and folding processes, non-woven fabric folding machines minimize material wastage. This not only contributes to cost savings but also aligns with sustainability goals, as less material ends up in landfills.

————

Part 5. Learn more:

The following picture shows the details of our Dust Bag Making Machine. If you want to know more about this machine, you can follow our youtube channel or email us for more details. And also you can follow our YouTube channel for comprehensive demonstrations or reach out via email for detailed information.

————

————

————

RELATED EQUIPMENT

RELATED EQUIPMENT