Revolutionizing Hygiene: The Innovative, High-Speed, Individually Packaged Non Woven Shoe Cover Making Machine

——

Welcome to the future of hygiene technology – the Non Woven Shoe Cover Making Machine, a remarkable creation by our company. This cutting-edge marvel introduces a trifecta of innovation, high-speed production, and the unique feature of individual packaging for each shoe cover. In an era where hygiene is paramount, this machine is designed to redefine standards. Let’s dive deeper into the exceptional features, technological advancements, performance enhancements, machine specifications, market positioning, and a visual showcase of our pioneering creation.

Key Features of The Non Woven Shoe Cover Making Machine:

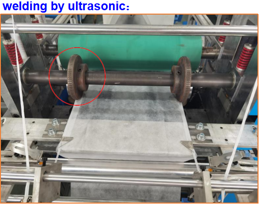

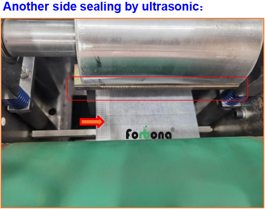

The Non Woven Shoe Cover Making Machine, a cutting-edge solution designed to revolutionize the production of shoe covers. This innovative machine utilizes PP nonwoven material, seamlessly welded together through ultrasonic technology. The finished shoe covers find versatile applications in both domestic and medical settings, catering to the unique needs of households and healthcare environments.

Material Compatibility: The machine excels in working with PP nonwoven material, ensuring optimal performance and quality in the production of shoe covers.

Versatility: Tailored for both civilian and medical use, the machine adapts seamlessly to various applications, meeting the hygienic standards required in hospitals and other environments.

Fully Automatic Operation: The Non Woven Shoe Cover Making Machine boasts a fully automatic operation from start to finish. This includes automatic feeding of materials, precise welding using ultrasonic technology, and the production of the finished shoe covers. The machine’s automation eliminates the need for manual intervention, ensuring efficiency and consistency in the manufacturing process.

Applications:The finished shoe covers produced by this machine are ideal for environments that demand high levels of hygiene, such as hospitals and other medical facilities. Additionally, the versatility of the machine allows for the production of shoe covers for everyday use in households, providing a reliable and effective solution for maintaining cleanliness.

Technological Innovations of The Non Woven Shoe Cover Making Machine:

Our company has spearheaded significant technological innovations and enhancements in the Non Woven Shoe Cover Making Machine. A key feature is the comprehensive utilization of ultrasonic technology throughout the entire process, ensuring a superior adhesive treatment for the end product. This innovation is complemented by a series of advancements, including the adoption of an aluminum alloy rack, providing a robust, durable, and solid structure. Additionally, the integration of an imported ultrasonic system with strong and stable power showcases our commitment to long-term continuous operation. Emphasizing these advancements underscores our company’s sensitivity to technological development and showcases our unwavering commitment to innovation.

Performance Enhancements of The Non Woven Shoe Cover Making Machine:

Our company has elevated the performance of the Non Woven Shoe Cover Making Machine, introducing a range of enhancements to ensure optimal efficiency, increased production speed, and extended operational lifespan.

1.Key Performance Improvements:

Enhanced Production Speed: The machine now operates at a significantly faster pace, delivering a smoother production process. With the capability to achieve speeds of up to 120 pieces per minute, it ensures a substantial increase in output.

Customizable Production Speed: Our innovative machine allows for customizable production speeds, providing adaptability to diverse production requirements. This feature empowers users to tailor the machine’s performance based on specific operational needs.

Improved Operational Stability: The upgraded machine ensures a stable and smooth operation, minimizing disruptions and enhancing overall reliability. This improvement contributes to consistent and high-quality production runs.

Higher Production Efficiency: With a focus on efficiency, the Non Woven Shoe Cover Making Machine now boasts improved energy efficiency, reducing operational costs while maintaining top-tier performance. This enhancement aligns with contemporary sustainability goals.

Extended Equipment Lifespan: Our commitment to longevity is reflected in the machine’s improved durability, resulting in a longer lifespan. This enhancement translates to a more reliable and cost-effective investment for our customers.

2.Detailed Features:

Ease of Operation: The machine remains easy to operate, ensuring user-friendly functionality. This user-centric design enhances the overall experience of machine operators.

Maintenance Convenience: Routine maintenance is made convenient, allowing for streamlined upkeep procedures and minimizing downtime.

Precision Electronic Counting: The machine incorporates precision electronic counting, facilitating accurate monitoring of production output. Automatic shutdown occurs once the set output is reached, contributing to operational efficiency.

Safety Measures: In the event of a broken shoe strap, the equipment features an automatic stop mechanism, ensuring safety and preventing any potential issues.

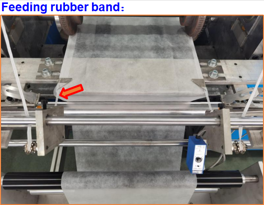

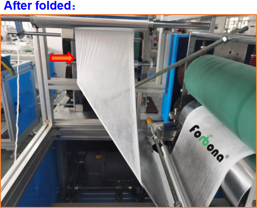

Automated Production Process: The machine follows an automated production sequence, from automatic feeding to nonwoven fabric binding, welding, folding, forming welding, cutting off, and finally, the output of finished products.

Material Compatibility: Applicable to 2540gsm thick nonwoven fabrics and accommodating raw materials with a width ranging from 330430mm, the machine ensures versatility in material usage.

The enhanced Non Woven Shoe Cover Making Machine reflects our dedication to delivering a high-performance, customizable, and efficient solution. These improvements underscore our commitment to providing advanced technology that meets the evolving needs of our customers while promoting sustainability and cost-effectiveness.

Machine Parameters of The Non Woven Shoe Cover Making Machine:

1. Introducing the Key Machine Parameters of Non Woven Shoe Cover Making Machine :

Model: AQ-SC400

Power Supply: 220VAC, 50/60Hz, 3KW, 1Phase

Ultrasonic Frequency: 20KHZ

Shoe Cover Size: 400*160mm

Production Speed: 100-120pcs/min

Dimensions (LWH): 25008001200mm

Net Weight: About 620Kg

Gross Weight: About 710Kg

2. Customer Benefits:

Cost Reduction: The Non Woven Shoe Cover Making Machine is engineered to reduce operational costs significantly. Its efficient design and automated processes contribute to resource optimization, making it a cost-effective solution for customers.

Heightened Production Efficiency: With an impressive production speed ranging from 100 to 120 pieces per minute, this machine ensures a rapid and efficient production process. This increased efficiency directly translates to higher output and quicker turnaround times.

Enhanced Reliability: The machine’s robust construction and thoughtful engineering lead to increased reliability. Customers can trust in its consistent performance, minimizing downtime and maintenance costs.

3. Practical Applications and Advantages:

The Non Woven Shoe Cover Making Machine finds invaluable application in various industries, particularly in healthcare and beyond. Its advantages lie not only in its precise parameters but also in its ability to cater to the real-world needs of customers.

Healthcare Settings: Ideal for hospitals and medical facilities, the machine produces shoe covers that meet the stringent hygiene standards required in healthcare environments.

Domestic Use: Versatile enough for everyday use, customers can benefit from the machine’s efficiency and reliability in maintaining cleanliness at home.

The Non Woven Shoe Cover Making Machine is not just a piece of equipment; it’s a strategic investment that brings tangible benefits to customers. By lowering costs, boosting production efficiency, and ensuring reliability, it emerges as a valuable asset for businesses seeking to elevate their operations and meet the demands of diverse industries.

Market Positioning of The Non Woven Shoe Cover Making Machine:

Positioned as a trailblazer in the market, our Non Woven Shoe Cover Making Machine proudly claims the title of being the first of its kind in China, featuring the unique capability of individually packaging shoe covers. Specifically tailored for the medical and healthcare industry, this innovative machine sets a new standard in meeting the industry’s requirements for hygiene and sterility.

Market Leadership: In the Chinese market, our Non Woven Shoe Cover Making Machine stands as the pioneer – the first machine capable of single-handedly packaging shoe covers. This groundbreaking feature positions it as a leader in innovation and practicality.

Ideal for Healthcare: With a primary focus on the medical and healthcare sector, the machine perfectly aligns with the stringent requirements for hygiene and aseptic conditions. Its design and functionality make it an indispensable tool for medical professionals and facilities.

Pioneering Development: Developed and manufactured by our company, this machine is a testament to our commitment to innovation and progress. By being the first to introduce such a groundbreaking feature, we underscore our dedication to pushing the boundaries of technological advancements.

Our Non Woven Shoe Cover Making Machine is more than just a piece of equipment; it symbolizes a paradigm shift in the industry. As the first of its kind in China, its innovative features cater to the specific needs of the medical and healthcare sector.

Visual Showcase of The Non Woven Shoe Cover Making Machine:

Our team is dedicated to providing comprehensive information, addressing your queries, and guiding you through the innovative features that make our Non Woven Shoe Cover Making Machine a game-changer in the industry.For an immersive understanding of our Non Woven Shoe Cover Making Machine, explore the intricate details through the accompanying visuals.

Whether you follow our YouTube channel for comprehensive demonstrations or reach out via email for detailed information, we invite you to witness the revolution in hygiene technology.The following picture shows the details of our Non Woven Shoe Cover Making Machine. If you want to know more about this machine, you can follow our youtube channel or email us for more details.

In conclusion, the Non Woven Shoe Cover Making Machine represents a pinnacle in nonwoven converting machinery. Join us in setting new standards for hygiene with this state-of-the-art, individually packaged shoe cover production solution.

——