Revolutionizing Healthcare: The Advanced Gauze Pads Making Machine

In the ever-evolving landscape of manufacturing, a cutting-edge Gauze Pads Machine has taken center stage, revolutionizing the production of cotton pads with its state-of-the-art features. Let’s delve into the intricate details of this groundbreaking equipment.

For Household First Aid and Cleaning:

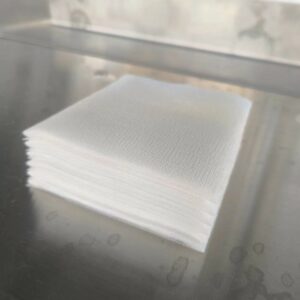

The products manufactured by the Gauze Pads Making Machine for civilian use primarily include various gauze pads for household first aid, cleaning, and general care purposes. These products are typically used for treating minor abrasions, cuts, or other mild injuries, providing convenient and effective care for everyday injuries. Civilian gauze pads often exhibit flexibility in size and material to meet diverse household needs.High-Quality Applications in the Medical Field:

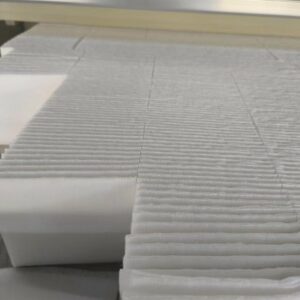

The Gauze Pads Making Machine’s medical products focus on producing high-quality gauze pads that comply with medical standards. These products are widely utilized in the healthcare industry for the treatment of severe injuries, post-surgical wound care, and other situations requiring sterile dressings. Medical gauze pads usually adhere to stringent quality requirements, ensuring the provision of reliable, sterile dressings in medical environments to facilitate wound healing and prevent infections. These products may have standardized sizes to accommodate various medical scenarios and comply with healthcare regulations.

The products manufactured by the Gauze Pads Making Machine for civilian use primarily include various gauze pads for household first aid, cleaning, and general care purposes. These products are typically used for treating minor abrasions, cuts, or other mild injuries, providing convenient and effective care for everyday injuries. Civilian gauze pads often exhibit flexibility in size and material to meet diverse household needs.High-Quality Applications in the Medical Field:

The Gauze Pads Making Machine’s medical products focus on producing high-quality gauze pads that comply with medical standards. These products are widely utilized in the healthcare industry for the treatment of severe injuries, post-surgical wound care, and other situations requiring sterile dressings. Medical gauze pads usually adhere to stringent quality requirements, ensuring the provision of reliable, sterile dressings in medical environments to facilitate wound healing and prevent infections. These products may have standardized sizes to accommodate various medical scenarios and comply with healthcare regulations.

Production Process Unveiled:

The Gauze Pads Machine follows a meticulously designed production process that ensures precision and efficiency:

Raw Material Transformation: The process kicks off with the seamless transfer of raw materials, setting the foundation for quality cotton pads.

Vertical and Horizontal Precision Cutting: Utilizing high-quality knives, the machine performs both vertical and horizontal cuts with unparalleled accuracy, eliminating burrs and ensuring high product precision.

Stepping Count and Array Outputting in Zigzag: The machine incorporates a stepping count mechanism, coupled with zigzag array outputting, providing a seamless and organized stacking of the finished products.

Machine Features:

Integrated Wall Panel Structure: The equipment rack boasts an integral wall panel, 35mm thick, eliminating the use of channel steel. This design choice prevents deformation during prolonged operation, ensuring continuous high product accuracy.

Superior Cutting Mechanism: Longitudinal and transverse slicing are executed with high-quality knives, providing precise cutting and a flawless finish.

Adjustable Size and Material Flexibility: The machine accommodates material widths up to 950mm and a jumbo roll diameter of 800mm. Finished product size, set at 50*60mm, is customizable within a broad range (Width≥4cm, length: 5-10cm).

Quality Construction: Vertical and horizontal cutters are crafted from imported, durable, and accurate-cutting special materials. The equipment also features a set of steel-to-steel indentation rollers with high-quality bearings.

Stainless Steel Components: All components in contact with fabrics are made of corrosion-resistant 304# stainless steel, ensuring hygienic production standards.

Smart Servo Control: Operated by servo driving systems, the machine offers a user-friendly interface with a well-organized layout of electric wires, facilitating ease of operation for workers.

Compact Design and National Originality: The entire structure is compact, high-speed, and boasts a smooth and stable performance, with minimal noise. It stands out as a national original, surpassing even Japanese makeup cotton in mechanical design.

Comprehensive Documentation: The machine comes with an English operation and technical manual, featuring detailed instructions and troubleshooting guides for user convenience.

Technical Specifications:

Production Rate: 1500-2000pcs/min

Rated Voltage: 380V

Rated Frequency: 50Hz

Total Power: 3kw

Machine Size: L:6500, W:1500, H:1600mm

Machine Weight: Approximately 1800kgs

In summary, the Gauze Pads Machine represents a leap forward in cotton pad production, combining cutting-edge technology, precision engineering, and user-friendly features to meet the demands of modern manufacturing.

————

————

————